High-Speed BLDC Motor Control Solutions

High-speed brushless DC (BLDC) motors are commonly used in various industries due to their efficiency, compact size, and high power-to-weight ratio. These are key components in Electric Vehicles, providing efficient and reliable propulsion, contributing to improved energy efficiency, and driving range.

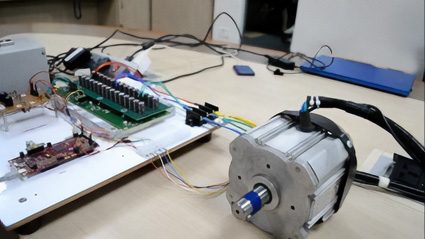

We, at Embitel, develop customized motor control solutions to operate modern high-speed BLDC motor up to 1,00000 rpm with six step trapezoidal control. High power to weight ratio makes BLDC motor ideal for high-speed applications where size and weight are crucial parameters to consider.

Interested in more details? Take it up with our consultants.

BLDC motor for high-speed application refers to having high efficiency, compactness, low cost & less maintenance. Our solution offers precise control over the motor speed and current even at high rotational speed.

Embitel’s control solutions of high-speed BLDC motor are intended to support blowers and compressors for medical application (dental drills, spindles, surgical tools, ventilator, respirator, centrifuges) and turbo charger application.

Our customized solution provides the control of high-speed BLDC motor both with position sensor (Hall sensor/ Encoder) and sensor-less operation. In recent days, Sensor less control gaining momentum with increased reliability particularly for ultra high-speed operation.

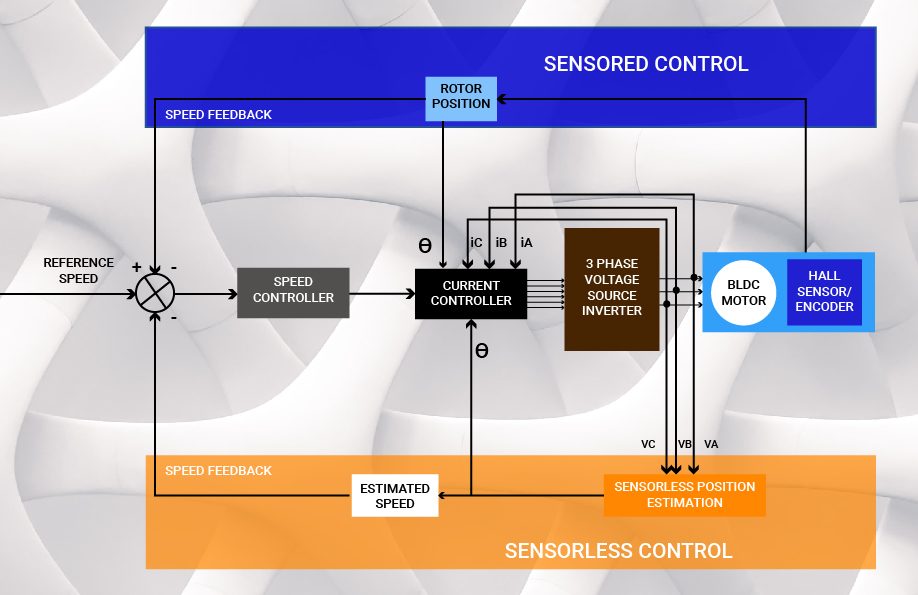

BLDC Motor Controller Architecture and Block Diagram

High-Speed BLDC Motor Control Solutions Offered by Embitel

Six step trapezoidal control with position sensor (Hall Sensor/Encoder)

It employs Hall Sensors or an Encoder to detect rotor position and switches the motor windings in a six-step pattern, ensuring efficient commutation and precise control of the motor's rotational speed and direction.

Sensor-less six step trapezoidal control

Sensor-less six-step trapezoidal control is a technique used to drive high-speed BLDC (motors without relying on external position sensors. It employs the back-electromotive force (EMF) information from the motor windings to approximate the rotor position, enabling efficient and cost-effective control in high-speed applications.

Closed loop speed control

Closed loop speed control is a sophisticated control system used for high-speed BLDC motors, where the motor's actual speed is constantly monitored and compared to the desired speed. The controller adjusts the motor's inputs, such as voltage or current, in real-time to maintain precise and stable speed, making it ideal for applications that demand accurate and efficient motor performance.

Current control

Current control in high-speed BLDC motors involves regulating the electric current flowing through the motor's windings to maintain precise torque and speed, ensuring optimal performance and stability during rapid rotational movements.

Critical Speed Control Application for Ventilator and Respirator – High-Speed BLDC Motor Control Solution Use Cases

For medical applications, the air delivery subsystem plays a crucial role in maintaining accurate pressure and flow control.

To meet this requirement, Embitel offers specialized BLDC motor drives designed specifically for air breathing equipment like ventilators and respirators. These customized solutions from Embitel ensure high performance, whether using sensored or sensor-less BLDC motors.

By employing our control solution, precise speed control can be achieved to match the desired air flow for ventilators. Additionally, our motor drives operate with minimal noise and vibration, enhancing the overall user experience.

Frequently Asked Questions

The magnitude of the current passing through the windings is directly correlated with the generated torque. Consequently, to put it simply, the brushless motor’s speed rises with higher voltage OR lower winding current (assuming one of these factors remains constant).

The speed control involves a combination of open-loop and closed-loop configurations. In open-loop control, the motor’s speed is regulated by directly manipulating the duty cycle of the PWM signal, which in turn controls the motor-drive circuitry.

BLDC motors are designed for high-speed applications and demand advanced speed control. Traditional control methods necessitate greater physical intervention to enable precise speed regulation of BLDC motors.