Hardware Design Services For Electric Vehicles, Telematics, Infotainment And Motor Controllers

Our hardware consulting, design and development teams have partnered with customers across US, Germany (and Europe), India, China, Taiwan, and South Korea.

We have collaborated with our customers to deliver production-grade hardware solutions for Digital Cockpit (Infotainment, Instrument Cluster, Head-up Display), Telematics and Electric Vehicles.

Our team of expert hardware consultants have more than a decade experience in hardware platforms like TI, Renesas, Infineon and other automotive grade MCUs.

Hardware Development: A Snapshot of our Domain Expertise in Automotive, Telematics, and Electric Vehicles

Automotive

Telematics

Electric Vehicles

Automotive

- Android Infotainment and Digital Instrument Cluster Solutions.

- Body Control Module (BCM).

- System for Motor Control for Power Steering, Seating Comfort, HVAC, Door Handle Lighting and more

Telematics

- Fleet Management Solutions.

- Track and Trace Systems for Bike/Car Sharing

- Insurance Telematics Solutions

Electric Vehicles

- Battery Management Systems

- DC-DC Converter, Charging Systems for Electric Vehicles

- Power Distribution System for EVs

- Electric Vehicle Powertrain

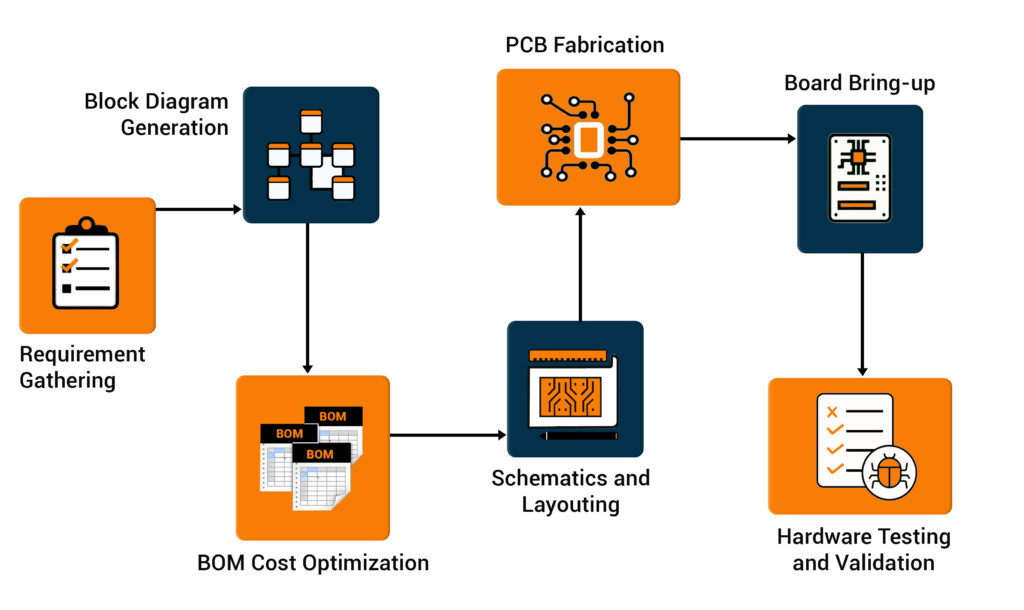

Hardware Design and Development Lifecycle: The Process Flow Diagram

Hardware Design and Consulting Services: ISO 26262 Compliance, EMC/EMI Testing

Requirement Gathering and Hardware Consulting

- Evaluation of requirements and Roadmap Planning.

- Requirement maturation to bridge any gaps in the understanding of requirements

- Evaluation of the Microcontroller Platform, based on the requirements and use-cases

- Estimation of the BOM cost, based on the specifications

Printed Circuit Board (PCB) Layouting and Fabrication

- Layering decisions for PCB based on high speed or low speed usage, track designing, and mounting of the components, based on the signals

- Expertise in Cadence Layout Tool, Mentorgraphics PADs tool

- Gerber file generation from Cadence tool or Mentorgraphics PADs tool for PCB Fabrication

- Support for Board Bring-up

- Gerber check using CAM350, Viewmate

Hardware Circuit Design and Schematics Design

- Selection of ISO/IEC standards based on the use-case of hardware

- Design of protection circuits based on standards

- Design of power circuit, Interfacing circuits such as Buck and Boost converter

- Support for Thermal Analysis, Signal Integrity Testa and Safety Mechanisms

- Schematics design using Cadence tool and Mentorgraphics PADs tool

- Optimization of the BOM Costs, based on the schematics

- Feasibility analysis for alternate component sourcing - cost, characteristics, footprint

- Component database maintenance

- Circuit simulation

Hardware Testing Services and Power-On Condition

- Filtering circuit to minimize the EMC/EMI as per CISPR standard.

- Support for Hardware Characterization for hardware bench level test and validation

- Support for EMC/EMI testing and Transient Testing

- Design of Test Plan for the Hardware Platform

- Unit test, Integration test and System Testing

Reverse Engineering Services for Hardware Development

Reverse Engineering proves to be a reliable method to revive and reuse a legacy system, for which the design architectures are not currently available.

It can also help in replication of a PCB for a project, thus, reducing the cost and time.

Our Hardware Reverse Engineering Services Include:

- Derivation of hardware schematics from the original PCB

- Support for estimation and optimization of the BOM cost

- PCB layout designing and fabrication

- Conversion of PCB to Gerber File

- Conversion of Gerber file to hardware schematics and layouts creation

- Board Bring up and Testing of reverse engineered board against the original board