For a vehicle to drive in an optimal manner, simultaneous communication between several vehicle ECUs is required. This communication is defined by protocols such as LIN, CAN, FlexRay and more. The protocol package must be tested rigorously for the communication to happen reliably.

Imagine a scenario where the engine control unit is not able to communicate reliably with an exhaust gas recirculation valve. This might cause the valve to not open when required, leading to excessive NOx emission. Such a scenario will lead to reduced power generation and fuel efficiency, not to mention, the increased pollution levels.

Vehicle ECUs that communicate through LIN are susceptible to many vulnerabilities. Faulty implementations, electromagnetic interference and improper source code are the main reasons for a LIN based system to fail.

Out of these reasons, the conformance of LIN protocol to LIN standard (ISO 17989) is one of the key aspects that automotive engineers must take care of. LIN conformance test is the method that helps to achieve this. If an automotive LIN device does not conform to the LIN protocol specifications, it may not be compatible with other devices in the network, leading to communication errors, data corruption, or even system failure.

Why is LIN Conformance Test Vital for Robust Automotive ECU Functionality?

LIN conformance test is a vital step in ensuring that automotive ECUs operate reliably and meet the requirements of the LIN standard. The test involves verifying the implementation of the different layers of the LIN protocol, which is responsible for message transmission, error handling, and bus arbitration.

By conducting conformance testing, automotive manufacturers can ensure that their ECUs will operate correctly in various scenarios and environments, minimizing the risk of failure and ensuring the safety and reliability of the vehicle.

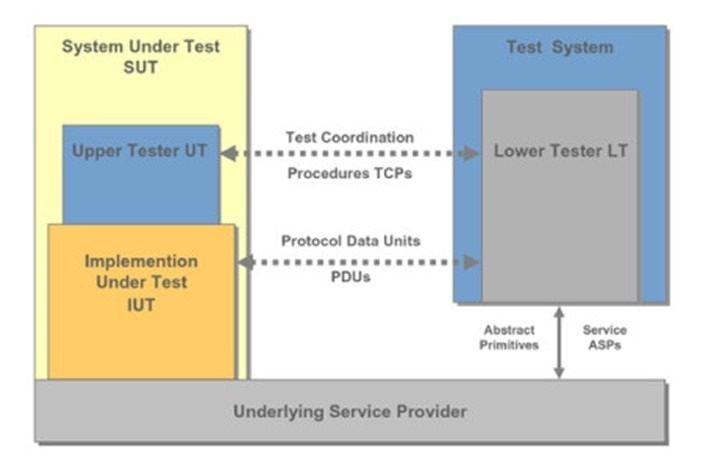

A Typical Protocol Conformance Test Setup

- Ensuring compatibility and interoperability: The LIN protocol is used in automotive electronics to communicate between various devices, such as sensors, actuators, and control units. If a device does not conform to the LIN protocol specifications, it may not be compatible with other devices in the network, leading to communication errors, data corruption, or even system failure.

- Improving reliability: The LIN protocol is designed to be robust and reliable, even in harsh automotive environments. The conformance test ensures that a device or system adheres to the protocol’s specifications, ensuring reliable communication and minimizing the risk of system failure.

- Validating functionality: The conformance test checks the functionality of the device or system in various scenarios and conditions, ensuring that it performs as intended. This helps to identify and fix any defects or bugs in the device or system before it is deployed in a real-world environment.

- Meeting automotive industry standards: The automotive industry has established standards for LIN communication, such as ISO 17987 and SAE J2602. Conformance to these standards is often required by automotive manufacturers and regulators. The conformance test ensures that a device or system meets these standards, enabling it to be certified for use in automotive applications.

What Exactly Do We Test in LIN Conformance Test?

LIN conformance test is a set of procedures used to verify whether a device or system adheres to the specifications of the LIN protocol. The purpose of the conformance test is to ensure that the device or system will work correctly in an automotive network that uses the LIN protocol.

It includes a range of tests that check various aspects of the device or system’s behavior, such as its timing, message framing, message content, and response to error conditions. The tests are designed to simulate various scenarios that may occur in a LIN network, such as different data rates, message lengths, and message formats.

There are different levels of LIN conformance tests, ranging from basic tests that check the basic functionality of a device or system to advanced tests that check its behavior in complex scenarios. The tests can be carried out using specialized test equipment, such as a LIN bus analyzer, or through software simulations.

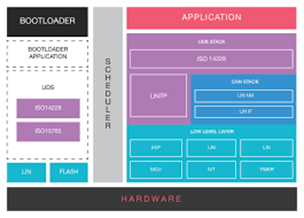

LIN protocol follows the OSI model where the LIN specifications cover the physical, data link and network layers.. And naturally so, all these layers are tested under LIN conformance test. The LIN conformance test specifications clearly define the fields of LIN Bus and LIN communications that need to be tested.

LIN Protocol Architecture

Now let’s quickly analyze how each layer is tested for conformance to LIN specifications:

- Physical Layer (OSI Layer 1): Testing the physical layer of LIN bus protocol generally covers the calibration part including operating voltage, signal voltages, shift test, duty cycle, propagation delay, loss of battery, loss of ground etc. This test essentially verifies the electrical compatibility of interfaces between LIN devices.

- Data link layer (OSI Layer 2): Data link layer of the LIN protocol is responsible for transferring data between the ECUs. The conformance test of data link layer checks for correct header, checksum, and response signals in the LIN messages sent and received by the interface. There is a set of test cases designed to cover various scenarios, including message transmission and reception, error detection and handling, timing, and bus arbitration.

- Network layer: In the LIN network layer, messages are transmitted in a Master-Slave configuration, where one node is designated as the Master and the other nodes are Slaves. There are certain test specifications that need to be covered while performing conformance test of network layer. Errors in either received frame or transmitted frame are tested, in addition to sleep/wake up tests.

- Application layer (OSI Layer 7): The LIN application layer defines the frame format, message identifier, and message content for the data exchanged between the ECUs. It is the top layer of the LIN protocol stack and is responsible for managing the application-specific data exchanged between the ECUs. Usual test cases for which application layer is tested include covering different message types, message formats, and error conditions.

How is LIN Conformance Test Performed?

LIN protocol conformance test is performed as per ISO 17987 part 6 which defines the test specifications. These test specifications essentially evaluate the LIN protocol according to ISO 17989 -2 and 3. The layers under test are data link layer, network layer and the transport layer. Physical layer of LIN protocol is tested under a separate part which is ISO 17987-7.

The conformance test consists of test cases that cover different aspects of the LIN protocol, including initialization, message transmission, and error handling. The test cases are designed to verify that the communication controller behaves correctly under different operating conditions and error scenarios.

The test cases are divided into 3 categories based on the type of LIN communication controller being tested, i.e., Master node, slave node and protocol implementation.

Each test case specifies the expected behavior of the LIN controller and the expected results of the test. The test cases are designed to be repeatable and deterministic, so that the same results can be obtained each time the test is run.

The conformance test requires specialized test equipment and software like LIN analyzer that can simulate a LIN network and perform the necessary measurements.

After the conformance test is performed successfully, a test report is generated which summarizes the results of the test and identifies any issues found during the test. The test report can be used to verify that the communication controller meets the requirements of the LIN protocol specification and to identify any areas where improvements may be needed.

Conclusion

As discussed above, the importance of LIN protocol conformance testing is huge as it enhances the reliability of the ECU communication in the vehicle.

In a nutshell, LIN protocol conformance testing is a crucial process for ensuring the quality and reliability of LIN devices. By performing these tests, manufacturers can ensure that their products meet the required standards, work seamlessly with other devices, and provide a better user experience.