Supervisory Control And Data Acquisition application, popularly known as SCADA system, is not a new kid on the block (in the Technology World).

SCADA systems have been accompanying Industrial Automation Solutions since time immemorial. These have been playing the role of eyes/ears (data collection), brain (data processing) and tongue (data insights communication) of an Automation System.

In its latest IoT avatar, the new generation SCADA system is a force to reckon with! SCADA 2.0 (powered by “Internet of Things” Technology Stack) is scalable, possesses more computation power, is cloud connected + mobile UI friendly and hence, available anytime-anywhere.

However, there is one pertinent dilemma that most of the businesses face when they kick-start this journey: The question whether they should invest in an off-the-shelf or custom-developed SCADA solution.

In order to help you find the answer, we have put together this blog. All our findings are based on our conversations with IoT consultants who have solid domain expertise in Industrial Automation.

In this blog, we talk about key technical and business factors to consider while choosing between an off-the-shelf and custom-developed SCADA.

SCADA System Build vs Buy – Business Considerations

- Degree of Freedom/ Ownership:When you custom-develop the SCADA application, you can opt to own the IP rights of the complete solution. This provides you the freedom to continuously upgrade or fine-tune the solution, as per your future business needs.

On the other hand, the IP rights of an off-the-shelf SCADA system are in control of your Product Vendor.

This means for any requirement related to change/upgrade requests, future scalability, quality management, etc., you are dependent on your SCADA application vendor.

- Cost Savings:When you invest in custom-designed SCADA solutions, the Total Cost of Ownership (TCO) depends on the following factors:

- Per unit cost (including the licensing cost)

- Number of units, as per the business requirement of your Industrial Automation project.

- Support and maintenance cost

When you invest in off-the-shelf SCADA solution, you can end up incurring higher costs. The following are some practical scenarios:

- Your business demands inclusion of functionalities, in addition to those provided by the off-the-shelf SCADA application. You can, in that case, work with your in-house development team to custom-develop these features. Other options are to either partner with a Solution Vendor (by negotiating the additional development cost) or buy an upgraded version.

- A new upgraded version of your existing off-the-shelf SCADA application is available in the market. In this case, your business needs to invest time and effort in checking if the upgrade will have an impact on the existing Automation System, and if any changes are needed in the existing systems/processes.

To summarize, more often than not, investment in a Custom-Developed SCADA solution is a CapEx (Capital Expenditure). As a business, you invest in a scalable solution that is entirely owned by your organisation.

- Testing and Maintenance Activities:In the case of custom-designed SCADA solution, you will require support from hardware and software engineers for the testing and maintenance activities.

However, in an off-the-shelf SCADA system, you can sign a contractual agreement with the solution provider or any other third-party vendor for the servicing and maintenance activities.

- Time to Market:As a rule of thumb, the time to market associated with a custom-developed SCADA system is more than the commercially available solutions. This is mainly due to the hardware and software development cycles.

On the contrary, an off-the-shelf SCADA package facilitates faster deployment, and hence, bears lesser time to market.

So, let’s summarise the pros and cons of each approach in the table below:

| Custom-Developed SCADA | Off-The-Shelf SCADA Solution |

| More flexibility to customise and make changes | You have to use the options provided by the commercial solution vendor |

| You own the IP rights of the entire solution | IP rights are with the solution vendor |

| CapEx for your business | Can turn out to be more costly, as it is a long-term investment |

| Support of teams with in-depth expertise in hardware and software system development, testing and maintenance is needed | Support and maintenance service contract can be signed with the SCADA solution provider or any third-party vendor |

| Greater time to market due to the presence of hardware and software development cycles | Comparatively lesser time to market |

Technical and Functional Aspects to Note

- Creation of Customised Data Insights that are Actionable: Consider that your industrial automation project is expected to perform the following tasks:

- Data ingestion and processing

- Interpretation of conditions or problems

- Setting alerts based on parameters

In this case, a custom-developed SCADA system is preferable. Why? Here are the top reasons:

-

- A SCADA solution tailor-made for your industrial infrastructure allows you to configure necessary data analytics to slice and dice the data, as per your unique business needs.

Data Slicing and Dicing refers to the process of segmenting, grouping, viewing and comprehending data within a database. Under these processes, large volumes of data are repeatedly segmented into smaller portions until the correct level of detail is achieved for proper analysis.

- A customised SCADA application offers better scope for integration with advanced Business Intelligence (BI) tools such as QlikView, Tableau, etc.This enables your organisation to have a unique view of the aggregated SCADA data, and convert this into actionable insights.

Thus, custom-built SCADA integration enables you to make the most of your enterprise data, beyond the traditional offerings of an off-the-shelf SCADA system.

- Automation of Maintenance and Field Service Workflows:When you own a custom-developed solution: You have the freedom to automate the maintenance workflow of your industrial equipment, whenever you intend to, with minimal downtime. How?

-

- You can define process programs to act as alternatives/aliases when a particular equipment, say the PLC/RTU, is being maintained. This way you can ensure that the maintenance activity doesn’t affect the overall system processes.

- You can implement custom process programs, unique to your industrial assets, to monitor and service them on time.

For instance, using custom programs an industrial equipment that requires maintenance can be configured to send automated service requests to the specific service vendor, using HTTP-based REST APIs.

- Additionally, you can leverage custom predictive analytics within the SCADA application to predict impending problems and perform predictive maintenance of your industrial plant.

With an off-the-shelf solution, you are totally dependent on your vendor, who will offer maintenance and service support based on pre-defined terms and conditions.

-

- Interoperability and Scalability: Industrial control systems are a heterogeneous mix of communication protocols and computing devices.Regardless of which SCADA integration strategy you intend to choose, it is necessary to ensure that the final SCADA system is compatible with:

- Operating System (Windows/Linux)

- Communication Protocols (Ethernet, Profibus or proprietary plant communications protocol)

- Different types of Remote Terminal Units (RTUs)

- External Devices/Applications from which SCADA can receive or send information/commands

An off-the-shelf solution may offer limited options in terms of compatibility with your industrial system. On the contrary, the technology architecture of a custom-developed solution can be designed to be compatible with various systems and protocols.

This way, these systems can also be scaled up to accommodate addition of industrial equipment in the future.

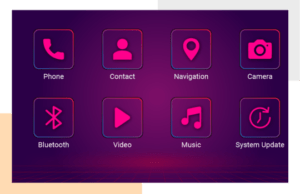

- Value-Adds of a Custom-Designed Human Machine Interface (HMI):A custom-developed HMI gives you more freedom in interacting with and managing your industrial assets.This is facilitated by features such as multilingual support, touch and gesture controls, and more.

With an off-the-shelf SCADA package, you may need to integrate external tools for improved visualization and interaction, that too at an additional cost.

Option to Validate Your SCADA System Design with a PoC:

In the case of custom-developed SCADA integration, you can take the Proof Of Concept (PoC) path and conduct a field trial of the prototype.

After validation of the capability of this SCADA PoC design, you can undertake the full-fledged enterprise production.

The PoC approach renders additional benefits like early-stage identification of potential mistakes and design flaws. This way, you can take the necessary corrective actions and overcome these challenges in the final custom-designed SCADA system.

Concluding Thoughts:

Performing a cost-benefit analysis of the above-mentioned parameters will help you decide between an off-the-shelf and a custom-developed SCADA application. The best SCADA solution is the one that easily represents your present and future needs!

Before making the final choice, it is always advisable to create a checklist of functional and business requirements of your industrial SCADA system. This could include need for remote access, interoperability, deep analysis of the industrial data, or highly customized HMI.

If the Build vs Buy SCADA dilemma still leaves you puzzled, you may take expert guidance from an experienced IoT consultant.